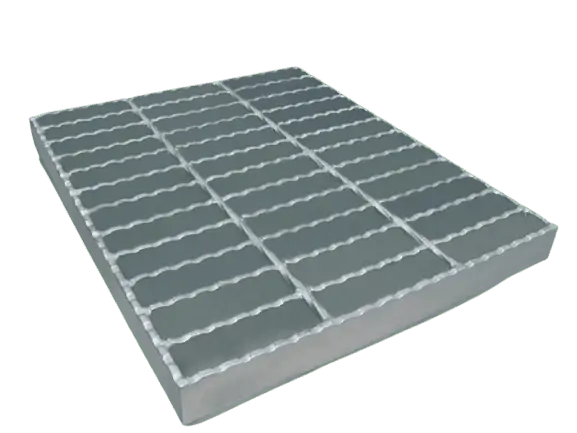

Welded Galvanized steel grating

The welded galvanized steel grating is made of stainless steel or low carbon steel. The welded galvanized steel grating is widely used in construction, petroleum, chemical industry, power plants, sewage treatment plants, food processing plants, and other industries. Electro-galvanized layers are thin and hot-dip galvanized layers are thick. In addition to being corrosion resistant, it is also anti-rust. There are two types of bearing bars in welded galvanized steel grating: flat bars and I-bars. Bearing bars are separated by a distance called pitch or pitch distance.

Metal Building Materials

Welded Galvanized steel grating

by Sunj Grating LimitedGalvanized steel grating is welded with low carbon steel or stainless steel. There are numerous industries that use it, including construction, petroleum, food processing, and others.