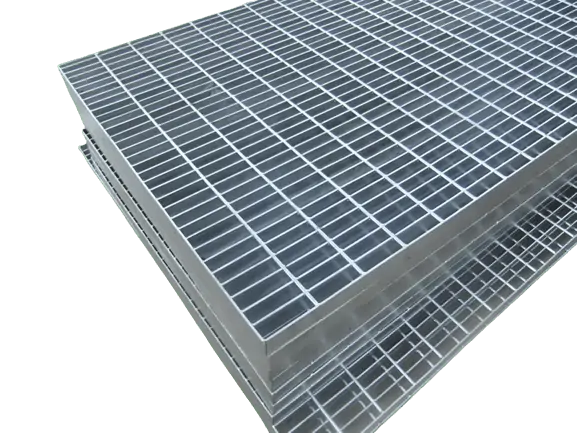

Hot-dip Galvanized Steel Grating

This process involves melting zinc ingots at high temperatures, adding some auxiliary materials, and then dipping structural metal parts into a galvanizing bath to attach a zinc layer to the metal parts. Among the advantages of hot-dip galvanizing are its strong anticorrosion ability, good adhesion, and hardness of the galvanized layer. After galvanizing, the weight of the product increases, and the amount of zinc we usually refer to is for hot-dip galvanizing.

Metal Building Materials

Hot-dipped Galvanized steel grating

by Sunj Grating LimitedThe use of hot-dip galvanized steel gratings is widespread, including in chemical plants, food processing facilities, water treatment facilities, and power plants.