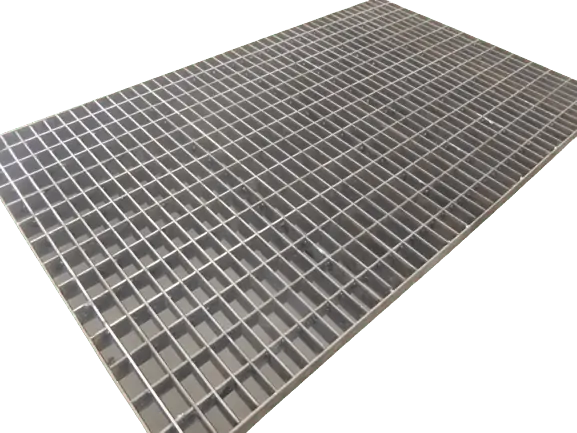

Flat Press-Locked Grating

Flat press-locked gratings have a smooth surface and come in several sizes. One of the main advantages of this type of grating is its ease of cleaning and maintenance. In areas where there is a risk of slipping, such as industrial plants or parking garages, it is slip-resistant as well. A flat press-locked grating product can be customized to fit your exact needs.

The Process Flow for Press-locked Steel Gratings

Step 1: Design Consultation(1-2 days)

In order to determine the most effective design for your project, our team of experts will consult with you before production begins. The final product will be used according to the intended use, the load dimensions and weight, the environment, and any other relevant factors. You can be sure that your steel gratings will last for many years to come if you follow these steps.

Step 2:Preparing raw materials(1-2 days)

In order to produce a quality product, raw materials are crucial. With our steel gratings, you can expect your product to meet or exceed your expectations because we only use the best materials available. We also source all of our materials from environmentally friendly and sustainable suppliers.

Step 3:Welding of steel gratings(5 days)

Following the finalization of the design and the sourcing of raw materials, the manufacturing process can begin. In the first step, pressure welding is used to join panels together. Panels are welded together using a high-pressure welding machine to create a strong, stable bond.

Step 4:Press-locking of steel gratings(3 days)

Welding is followed by finishing in the products workshop. During this step, any necessary cuts or holes are made, and the gratings are inspected to ensure they meet our high standards. Our clients receive the gratings after they have passed inspection.

Step 5:Step 4:Products Finishing(3 days)

Steel gratings are finished in the products workshop after they have been welded. Our final inspection ensures that the gratings meet our high standards by making any necessary cuts or holes. Our clients receive the gratings after they have passed inspection.

Step 6:Quality Inspection(1-2 days)

Steel gratings are finished in the products workshop after they have been welded. Our final inspection ensures that the gratings meet our high standards by making any necessary cuts or holes. Upon passing inspection, the gratings are ready for shipping.

Step 7:Packaging(1 days)

Steel gratings must be packed with special care and attention in order to prevent damage during transportation. We use high-quality packaging materials to ensure the products are not damaged during transportation. Each grate should be wrapped in plastic film, placed in a box or crate, and filled with packing material such as styrofoam peanuts or bubble wrap. The box or crate should be sealed with tape and labeled with the contents and the date. Steel grates will be protected from rust and corrosion during storage or transportation if you follow these packing tips.