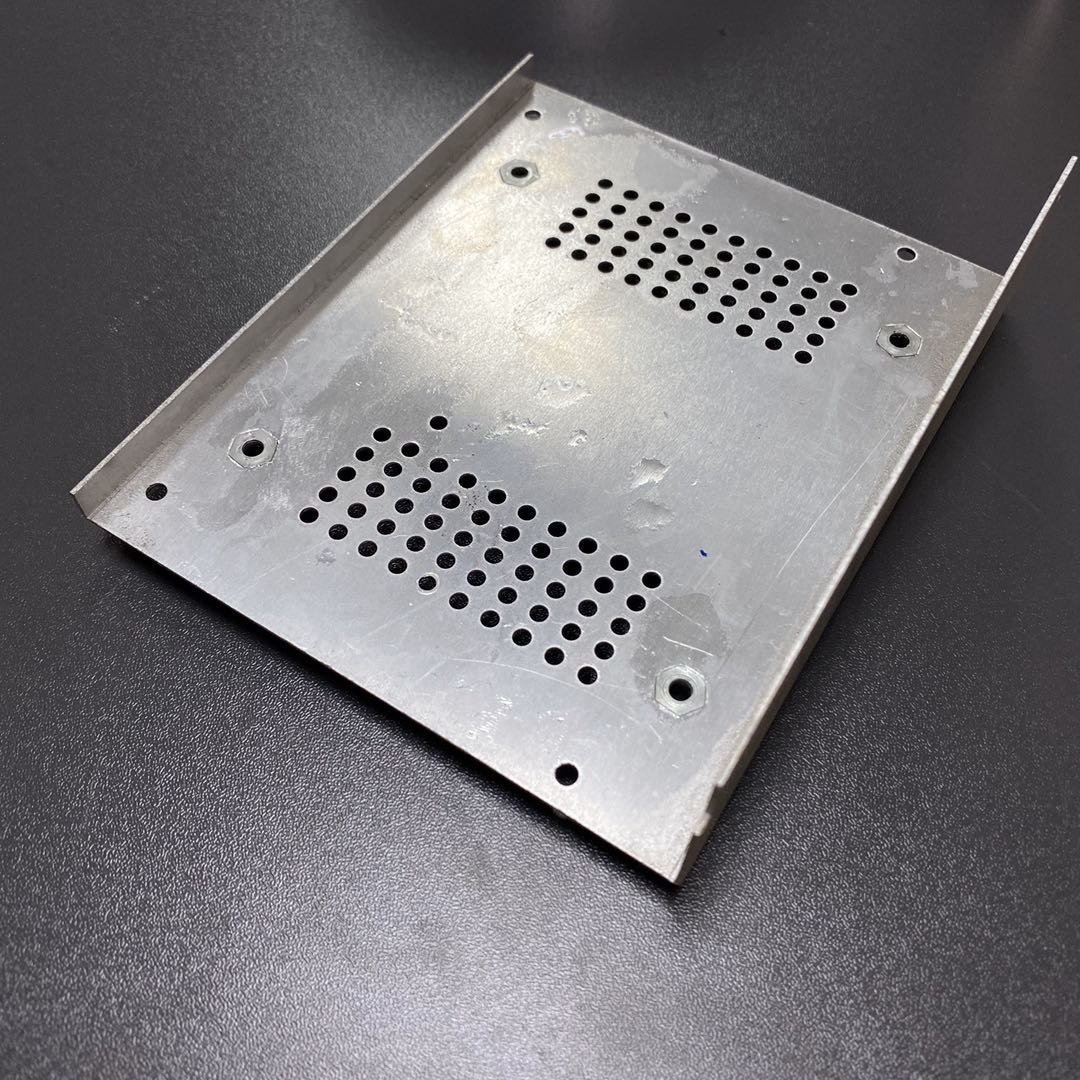

Aluminum stamping parts characteristics

One of the light metal materials is an alloy based on aluminum with other alloying elements. Due to the different types and amounts of alloying elements, aluminum alloy has some specific properties in addition to its general properties. Aluminum alloys have a density of 2.63 ~ 2.85g/cm3 and a high strength (σb is 110 ~ 650MPa). The properties of aluminum stamping parts are widely used in various fields:

Casting performance and plastic machining performance are good

Weldability, corrosion resistance, and good electrical and thermal conductivity

Recyclable and non-toxic

The material grade of aluminum stamping parts

Stamping operations usually alloy pure aluminum with other metals to increase or enhance certain material properties to improve the final product’s performance. A typical alloy consists of copper, iron, magnesium, manganese, silicon, and zinc:

Series 1000. Among all series, they contain the most aluminum. More than 99.9% purity can be achieved. The production process is relatively simple, and the price is relatively low since it doesn’t contain other technical elements. In conventional industries, it is the most commonly used series. The most common products in circulation are 1050 and 1060.

Copper content ranges from 3-5% in the 2000 series, characterized by high hardness. The 2000 series aluminum plate is aviation aluminum, which is not commonly used in traditional industries.

They are also known as rust-resistant aluminum 3000 series. The main component is manganese, which has a content between 1.0-1.5%. It has good anti-rust properties.

They are part of the higher silicon series, the 4000 series. With a silicon content of 4.5-6.0%, a low melting point, and good corrosion resistance, it is often used to manufacture building materials, mechanical parts, forging materials, and welding materials.

There are three to five percent magnesium in the 5000 series, which is a more commonly used alloy aluminum plate series. Aluminum magnesium alloy is another name for it. Among its main characteristics are low density, high tensile strength, and high elongation. The weight of aluminum magnesium alloy is lower than that of other series in the same field. Consequently, it is commonly used in aviation, such as aircraft fuel tanks.

A representative grade of the 6000 series is 6061, which is a cold-treated aluminum forging product suitable for high corrosion resistance and oxidation requirements. Good workability, good interface characteristics, easy coating, good processing capabilities.

The 7000 series is an aluminum-magnesium zinc-copper alloy with heat treatment and good wear resistance.

The 8000 series of aluminum plates are used for making bottle caps, as well as radiator foil.

We have been involved in customer projects from concept to mass production as a manufacturer and supplier of metal stamping parts to ISO9001. It is the best choice for customers to choose a company with reliable quality and a professional team.