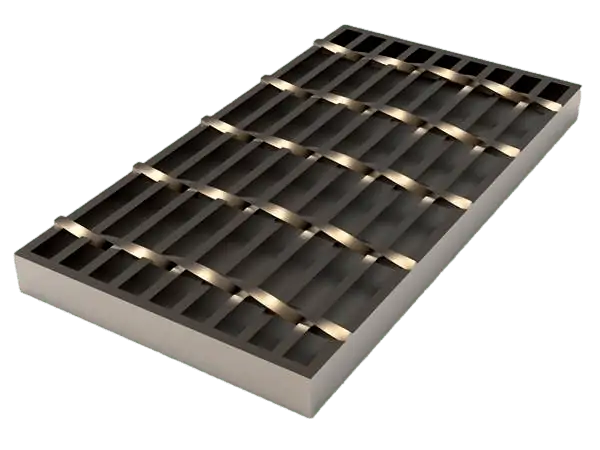

Stainless steel Heavy-Duty Steel Grating

Its long bearing bars make it a popular type of heavy-duty steel grating. In many fields, such as construction, machinery protection, ventilation grilles, and so on, it is used. There is no restriction on the intervals at which the bearing bars can be placed to meet different needs. In conjunction with the bearing bars, the cross bars are welded, pressure-locked, or riveted together. As a result, these heavy-duty steel gratings are load-bearing and anti-slip.

Metal Building Materials

Stainless steel Heavy-Duty Steel Grating

by Sunj Grating LimitedKnown also as galvanized bar grating, galvanized steel grating is available in a variety of sizes.