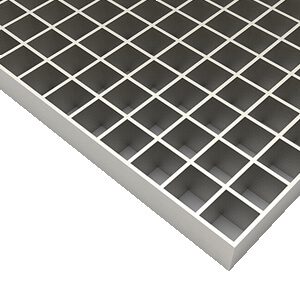

Press-Locked Stainless Steel Gratings

A press-locked stainless grating consists of bearing bars and cross bars. A grating’s bearing bar is its main load-bearing component. Various thicknesses and depths are available. A variety of thicknesses are available for the crossbar, which is the secondary load-bearing component of the grating. In order to join the two types of bars, a high-pressure process is used. The result is a joint that is rigid and strong.

The Process Flow for Stainless Steel Gratings

You should ensure that the gratings are of the highest quality. There are a few crucial steps in the manufacturing process. The gratings will be defect-free and have a long lifespan if these steps are followed. The following is an outline of the process flow for manufacturing gratings: